About Global Lift Used Forklifts Tacoma

Global Lift Tacoma - Buying a forklift is something you must carefully think about. A forklift is a large capital expense, and a complex equipment with a motor strong enough to carry out heavy-lifting jobs. The price tag for a forklift ranges from ten thousand dollars to thirty thousand dollars, comparable to the cost of a small truck. If buying a second-hand forklift, be sure to have it checked for possible mechanical problems.

The two types of forklift motors are: internal combustion or electric. Forklifts with electric motors are usually more pricey compared to forklifts with internal combustion motors. The size of the motor must suit the kind of work for which the forklift will be used. A forklift with a large motor costs a lot more compared to a forklift with a smaller motor.

Motors that use propane or gasoline can lift heavier weights as they are usually stronger than electric motor. The disadvantage is that gas motors tend to develop issues more often than electric motors. Depending on the price of gas or propane, gas powered forklifts can be more costly to run compared to electric powered forklifts.

Several reliable manufacturers of forklifts are Crown Equipment Corp., Mitsubishi Caterpillar, NACCO Industries and Toyota Industries. Before deciding, research the various manufacturers and the availability of parts. Prices, reviews and testimonials can be found on the Web.

In the US, twenty thousand individuals are injured each year in accidents related to the utilization of forklifts. And each year around 100 deaths are caused by forklift accidents. Fortunately, correct training about operation procedures and maintenance could considerably reduce the chance of accidents. The basic safety rules and tips below should be followed whenever utilizing a forklift.

It is the job of the employer to make sure that the correct training program is given to the employees and that operators of forklifts are trained.. Training includes a combination of lectures, presentations, discussions and practical hands-on training. Reevaluation must occur every three years. Operators of forklifts should be up-to-date with current forklift safety rules. Forklift training program content includes general workplace hazards, dangers of forklift operations, workplace surfaces and lighting, and dangers connected to using the specific forklift which the employee will be using. An employee must be at least eighteen years old to operate a forklift.

Forklift inspections must be carried out daily to guarantee the safe and proper functioning of the machinery. The inspection includes keeping a checklist of items and reporting any problems at once.

Having a safe and clean workplace is vital in the safe use of a forklift. A safe work place means establishing "traffic lanes" which are only designated for forklift use. Warning systems like horns and flashing lights should be in place to be able to indicate when there is an approaching forklift. Forklift docking stations should be inspected daily and kept in good repair.

Included in the general safety rules of utilizing a forklift are ; respecting the load capacity of the forklift and never going over the maximum; lowering or raising the load only when the forklift is stationary; ensuring there is enough clearance for the load; and keeping arms, legs and hands inside the vehicle while using it.

Forklift certification courses really help to make certain that businesses utilizing forklifts, comply with the local and regional rules. The operators of the forklift must go through forklift certification before operating this kind of equipment. Training is still helpful and effective for people seeking distributing and industrial jobs within the places that certification is not required by law. Those who are certified are normally selected over other applicants due to this particular training. Forklift drivers who are certified are usually paid higher as opposed to individuals who are not licensed. For businesses, having correctly trained forklift operators means fewer workplace accidents, better productivity and fewer product damage during unloading and loading. When businesses follow governmental rules by providing training to their employees, they can achieve better ratings on their safety inspections, potentially reducing insurance costs.

Formal forklift training is suggested to help workers and supervisors receive licensing. It would be easier for individuals with a forklift certification to search for warehouse jobs since the license would show to prospective employers that the person has specific required skills. A forklift license is suggested due to the advantages to both the business and the employee. A skilled operator saves resources due to fewer accidents, that means savings on expenses associated with time lost or hospitalization. A forklift operator who is licensed can be depended upon to work more efficiently and effectively than one who is untrained.

A formal forklift certification training program can differ in length depending upon the type of forklift utilized in the instruction, class size, and aptitude and experience level of trainees. Certification often needs the trainee to pass a practical exam and written test before a license can be issued. Upon successfully completing a formal training program, graduates would be qualified to obtain work in various industries.

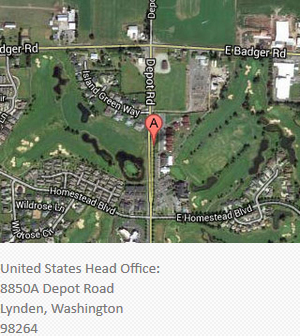

Contact Info

Questions or Comments